Proper use increases the farmer’s profitability

For effective feed broadcasting by the auto-feeder in semi-intensive shrimp culture ponds, the spout of the feed dispenser should be about 80 to 100 cm above the surface of the water. The higher the hopper is above the water, the larger the feed broadcast area will be. However, in small intensive ponds where it is necessary to reduce the feeding area, the feeder spout should be only 50 cm above water surface.

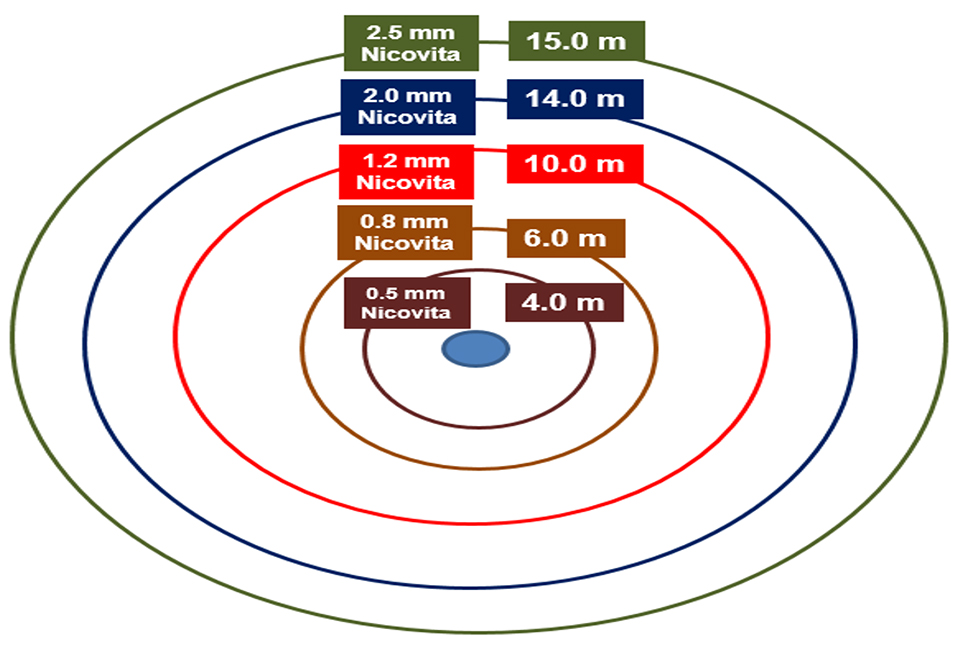

In addition, the size of the pellet also affects the feeding area, because the larger the pellet, the further it spreads, as we can see in the following figure:

Another variable to consider is the dissolved oxygen concentration in the feeding area, because oxygen consumption by the hundreds of thousands of shrimp that congregate below and near each auto-feeder may deplete oxygen levels, making necessary the placement of mechanical aerators nearby.

The placement of auto-feeders at the optimum water depth is also important for a uniform distribution of shrimp for each feeder. Field experience tell us that the best water depth range for an auto-feeder in a pond without aeration is 1.00 to 1.30 meters, while in intensive ponds with strong aeration the best range is 1.40 to 1.60 meters. Uniform water depth and dissolved oxygen concentration in the area of automatic feeding results in an optimum distribution of the shrimp population in the pond.

Editor’s note: Readers interested in more detailed information can check the following reference available (In Spanish) from the author: Ching C.A. 2017. Cómo incrementar la rentabilidad del cultivo de camarón con una adecuada implementación tecnológica. Aqua Expo Guayaquil, Ecuador 2017.

Evaluating shrimp biomass capacity per auto-feeder

Field results conclude that the appropriate biomass per feeder hopper results in better shrimp growth, FCR and survival rate of the shrimp. For instance, in semi-intensive shrimp production in large ponds (more than 4.0 ha.), the maximum biomass recommended for auto-feeding is 2,000 kg of shrimp per hopper. For intensive farming in small ponds (less than 1.0 ha.) with strong aeration, the maximum biomass recommended is 4,000 kg of shrimp per hopper.

Exceeding the biomass capacity of an auto-feeder can result in lower growth rate, higher FCR and lower survival rate of the shrimp, mainly because of the faster deterioration of water and soil quality resulting from an increase of organic matter and low oxygen concentration. In addition, a larger feeding load per hopper will reduce the life of the batteries, motor and other parts of the auto-feeders.

Bioremediation of the feeding area

During a shrimp production cycle and after harvest, the automatic feeding area requires bioremediation. The proper application of beneficial bacteria – like Bacillus subtilis and Lactobacillus spp. – is necessary to help maintain pond soil and water in adequate conditions, and support stable production of shrimp over time.

Evaluating auto-feeding techniques

Trials done by Kasetsart University during intensive culture of Pacific white shrimp at farms in Thailand showed the advantage of using automatic feeding over manual feeding, with the best results obtained with auto-feeding with sound detection using hydrophones (Table 1).

Ching, automatic feeding, Table 1

| Parameter | Hand feeding (4X) | Timer feeding | Sound-detection feeding |

|---|---|---|---|

| Feed conversion ratio (FCR) | 1.55 | 1.42 | 1.30 |

| Average daily growth (ADG) | 0.18 | 0.21 | 0.24 |

| Mean harvest weight (g) | 15.92 | 16.94 | 24.52 |

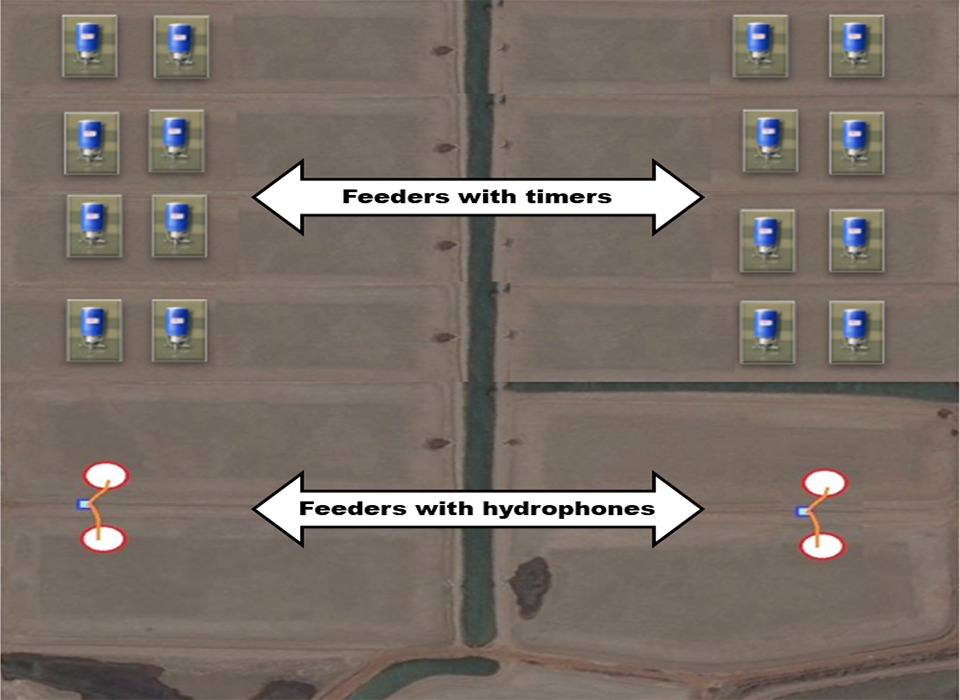

A strategy used by some shrimp farmers in Ecuador to decrease the equipment investment costs associated with automatic feeding is to set up one sound detection feeder to monitor feeding activity by the shrimp, and then use this information with the auto-feeders with timers in a determined area of the farm. Programing of the auto-feeders with timers follows the curve of feed consumption of the auto-feeder using hydrophones to detect the sound of shrimp feeding activity. Later, feed consumption is verified by feed trays placed near the auto feeders.

Perspectives

The basic but important considerations I have described for the proper use of auto-feeders in shrimp ponds can significantly help improve the profitability of shrimp pond culture.

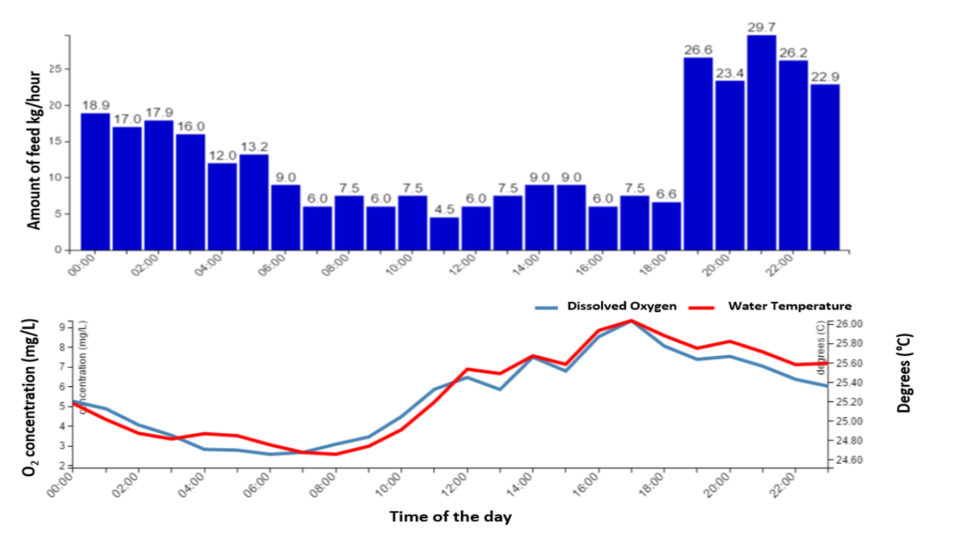

It is also relevant to mention that, in many cases but not always, there is not a strong correlation between feed consumption and water temperature or dissolved oxygen concentration. Further studies with auto-feeders and water quality sensors are needed to better understand and predict shrimp feeding behavior at different times of the day/night, and between seasons.

Automatic feeding with the use of sensors for various water parameters – such as dissolved oxygen concentration, temperature, pH, alkalinity and rainfall – can be important tools for improved understanding of shrimp feeding behavior, and thus help manage feed more efficiently and decrease the highest cost in shrimp farming.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Dr. Carlos A. Ching

Technical Assistance Manager, Nicovita – Vitapro Ecuador

[99,101,46,109,111,99,46,112,114,111,99,105,108,97,64,109,103,110,105,104,99,99]

Tagged With

Related Posts

Aquafeeds

Automatic feeding in shrimp aquaculture

Controlled by timers, automatic feeders should be placed in deeper areas of ponds and away from aerators. Overfeeding is rare during automatic feeding, and pond bottom quality is maintained through grow-out cycles.

Aquafeeds

Automated feeding systems in pond production of Pacific white shrimp

Results of this study show that automated feeding systems are significantly more efficient than hand feeding in shrimp production ponds and that increases in feed input, application of adaptive technology and training of people to maintain the feeding system must all be considered.

Innovation & Investment

Aquaculture Exchange: Mike Velings, Aqua-Spark

Dutch investment firm Aqua-Spark has in just two years developed a modest portfolio, but a strategy that is poised for growth and impact across the entire aquaculture value chain, its CEO and co-founder told the Advocate.

Innovation & Investment

Eight digital technologies disrupting aquaculture

Eight digital technologies are disrupting aquaculture and having a profound impact on the way business operates – even displacing some established ones.