Arroyo Aquaculture Association meets more stringent waste discharge regulations

Recent shrimp farming technology called for high rates of pond water exchange as a means of maintaining water quality by flushing out organic waste and excessive phytoplankton. However, this approach transports dissolved and suspended wastes into receiving water bodies, where excessive enrichment can occur. A major challenge facing shrimp farmers is the development of cost-effective technology for reduction of water use and waste discharge. This paper describes the experiences of the Arroyo Aquaculture Association (AAA), a cooperative shrimp farm in south Texas, in developing technology to meet more stringent water discharge regulations.

History

The AAA facility was constructed in 1989. It consists of 85 intensive ponds of 2-hectares each. Water is drawn from and discharged to the Arroyo Colorado River, where salinity typically varies from 6 to 20 ppt. In the farm’s initial years, shrimp were produced using high stocking densities (50 per square meters), high protein feed (35 to 40 percent) and a high water exchange rate (10 to 20 percent per day). These practices yielded profitable production, but also raised concerns over the quality of water discharged from the farm. In these early years, the farm would discharge upwards of 230,000 cubic meters of water per day. The discharge water contained total suspended solids (TSS) as high as 100 ppm and total ammonia (NH3) readings as high as 3 ppm. It became imperative to reduce these levels in order to qualify for a discharge permit from the Texas Natural Resource Conservation Commission (TNRCC).

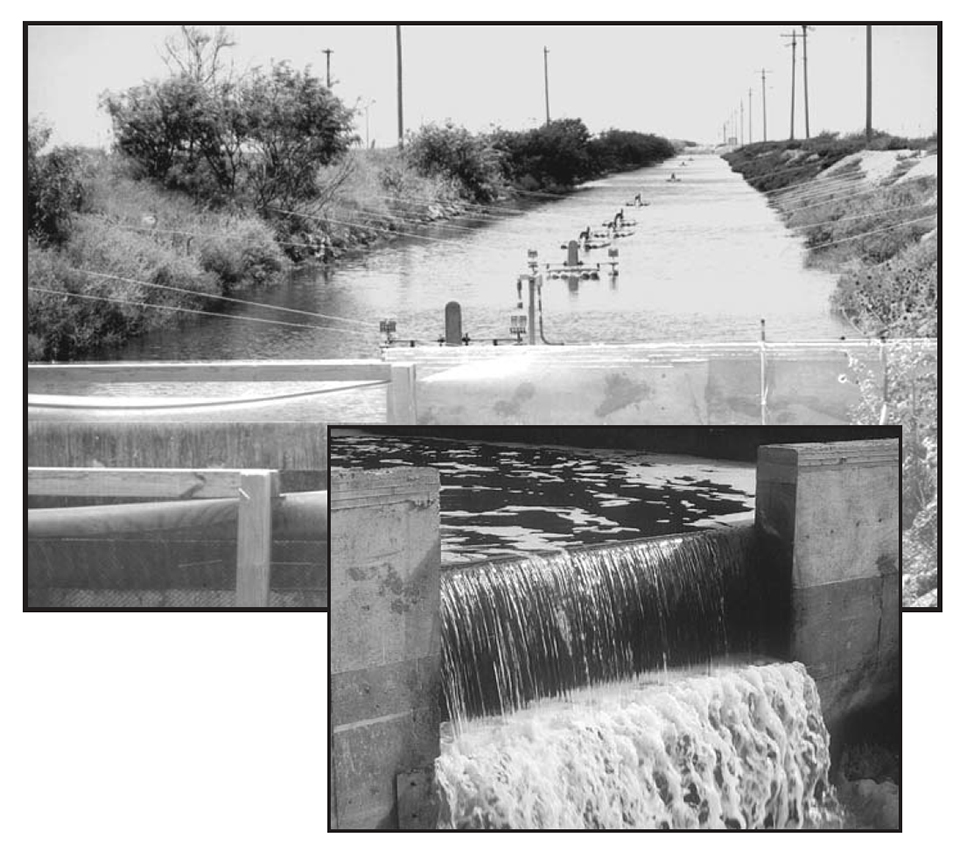

Modification of drainage ditches

In order to meet standards proposed by TNRCC, AAA implemented a water improvement project. The water drainage system was reconstructed by widening all drainage ditches, constructing weirs, and adding aeration and water reuse pumps.

During the growing cycle, water that is discharged from shrimp culture ponds enters into the drainage/recirculation system. This system consists of over 6.5 km of drainage ditches, which have been converted to sedimentation and aeration areas. Ditches which were originally 3 meters wide, and 0.3 meters deep have been expanded to 12 meters wide and 3.0 to 3.5 meters deep. These ditches also have been weired, so maximum depth can be maintained throughout the system.

Prior to these improvements, water passed through the ditches at a rate of 1.5 to 2.5 meters per second. After widening and weiring, water now moves through the ditches at a rate of less than 0.15 m per second. This reduction in velocity allows suspended solids to settle from the water column. These ditches are also aerated to help degrade ammonia and CBOD.

Water quality measurements at a recirculation pump, where the water entered the fill canal indicated no increase or only slight increases in phosphate and nitrite throughout the growing cycle. Increases did occur in total ammonia (0.1 to 1.33 milligrams per liter), nitrate (0.2 to 3.8 milligrams per liter), total suspended solids (10 to 70 mgmilligrams per liter), volatile suspended solids (1 to 17 milligrams per liter), and carbonaceous biochemical oxygen demand (0.1 to 1.8 milligrams per liter).

Modification of pond management

AAA also implemented management changes to improve pond water quality. Management changes consisted of reducing stocking densities (35 per square meter), reducing feed protein levels (30 percent), increasing pond aeration (18 horsepower per acre), increasing feedings per day (3 to 4), and more strictly monitoring pond parameters. Ponds that do not meet certain water criteria are not permitted to discharge into the drainage system.

The biggest challenge in operating this system has been the management of in-pond dissolved oxygen levels. As the production cycle progresses, a gradual greening of the ponds occurs. This is primarily caused by the increase in total ammonia in the recirculating system. To combat this problem, AAA has increased pond aeration to as high as 30 horsepower per hectare, increased the number of emergency aerators, and increased aeration in the ditches to 100 hp. With these structural and management changes, AAA has been successful in growing crops of shrimp profitably and complying with the regulations set by TNRCC.

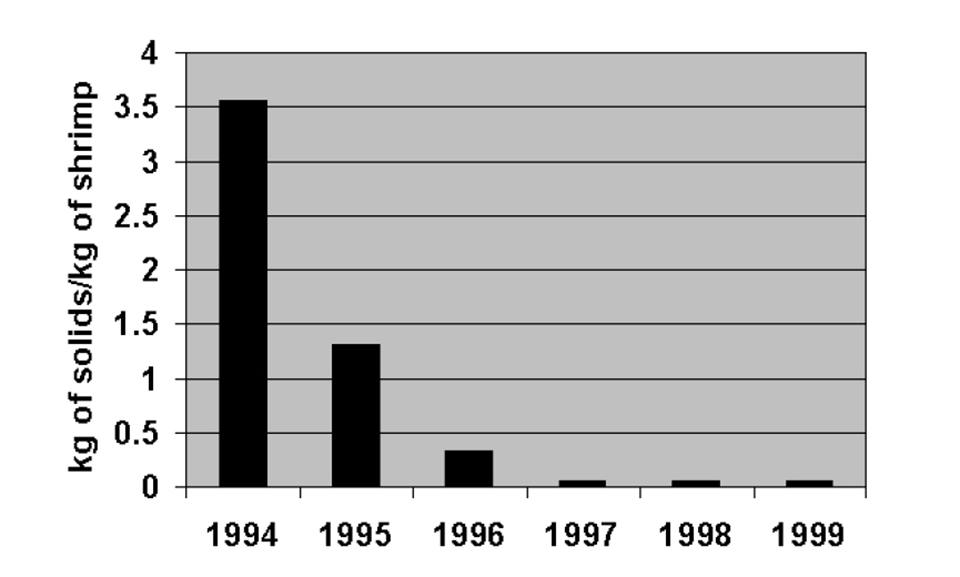

Reduction in waste discharge

From 1994 to date, AAAhas maintained production levels of 3,600 to 5,400 kilograms per hectare with the exception of 1995, when Taura Syndrome virus infected the facility. Satisfactory production levels were maintained, even though stocking densities and feed protein levels were reduced. The waste load on the receiving stream also was dramatically reduced. In 1994, for every kg of shrimp produced 3.56 kg of solids were discharged to the receiving stream, while in 1999 only 0.05 kg were discharged for every kg produced (Fig. 1). Similar reductions have been achieved for the other parameters. In 1994, 0.1192 kg of carbonaceous biological oxygen demand (CBOD) was discharged per kg of shrimp produced compared to 0.0088 kg in 1999. Likewise, total ammonia discharged per kg produced was 0.0942 kg in 1994 and 0.0003 kg in 1999.

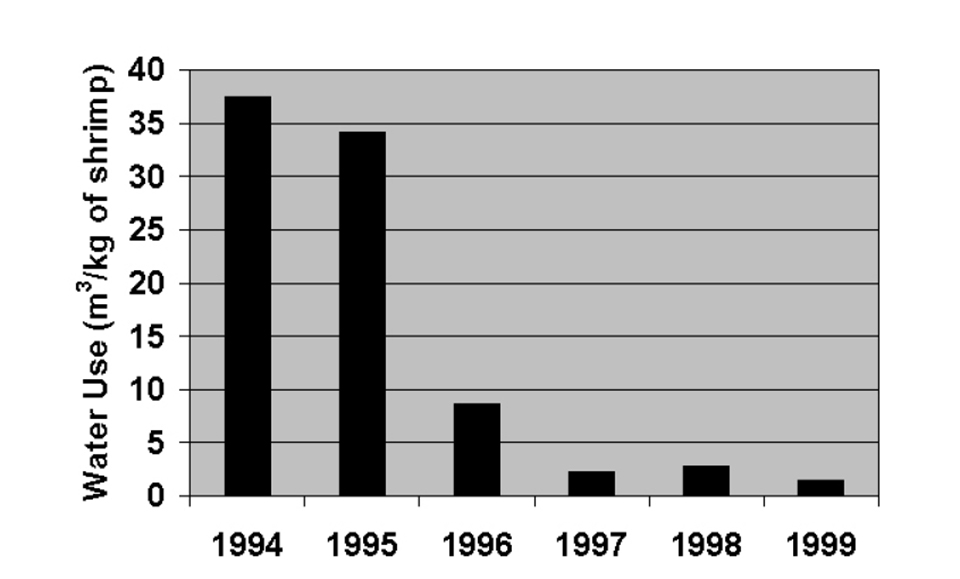

Reduction in water use

One of the most dramatic changes that have been accomplished by AAAis the reduction in water use from 37.6 to 1.5 cubic meters per kilogram of shrimp production (Fig. 2). Water is pumped from the Arroyo Colorado during the months of March, April, and May for initial filling of the ponds. After this point, additional water is pumped only to make up for evaporation.

Conclusion

Arroyo Aquaculture Association has been successful in reducing water use from 37.6 to 1.5 cubic meters per kilogram of shrimp production without sacrificing production rates. Waste discharge has declined in step with declining water use. Ponds are filled during March, April, and May and drainage water is reused thereafter, except for occasional replacement of water lost through evaporation. Pond management was modified to reduce the waste load entering drainage ditches. This involved reduced stocking density, reduced feed protein, and increased aeration. In addition, drainage ditches were modified to facilititate sedimentation of solids, oxidation of organic waste, and water reuse. This involved widening and deepening ditches and equiping them with weirs, aeration, and reuse pumps.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Louis Hamper

Harlingen Shrimp Farm

363836 Marshall Hutts Road

Rio Hondo, Texas 78583 USA

Tel: (956) 748-3976[109,111,99,46,115,99,64,114,101,112,109,97,104,115,105,117,111,108]

Tagged With

Related Posts

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Intelligence

4-hexylresorcinol: sulfite-free control for melanosis in crustaceans

4-hexylresorcinol in a nonsulfite processing treatment against melanosis in crustaceans inhibits natural enzymes for shell hardening.

Health & Welfare

A case for better shrimp nutrition

Shrimp farm performance can often be below realistic production standards. Use proven nutrition, feeds and feeding techniques to improve profitability.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.