Practice helps improve effluent water quality

Because wasted feed is costly and leads to reduced water quality, optimizing feeding practices is a critical management issue in shrimp farming. Broadcasting feed throughout a pond – manually or mechanically – is the most widely used method to apply feed. A few feeding trays may be used to monitor feed consumption and estimate adjustments to ration size.

However, observation of feed consumption from a limited number of trays is not an adequate measure of actual feed consumption, especially in large ponds. There are considerable day-to-day variations in feed consumption due to water quality fluctuations, overcast skies, lunar cycles, molting activity, and natural food availability. In Brazil, shrimp farmers have successfully adapted the use of feeding trays to distribute all feed in ponds, obtain a more accurate estimate of feed consumption, and estimate adjustments.

Tray design and construction

Circular feeding trays originally developed in Peru were introduced to Brazil in 1993, and were quickly adapted by farmers for local use. The trays, composed of rubber and steel, are made from the core of car tires. Used tires are adequate because they are less expensive and will still last longer than other materials, such as wooden rods. Weights are not needed to keep the trays submerged. Truck tires, however, are not used due to their heavy weight.

Trays have an internal diameter of 51 cm and a height of 4 cm. A 1.3-mm diameter mesh net is fixed on the bottom with screws and a piece of rubber. Ropes are installed on the sides of each tray to allow retrieval from water. Wooden sticks or PVC pipes filled with cement are used as anchor poles for trays. The anchor poles are tapered at the top to discourage birds from perching on the poles.

Number of trays used

High labor requirements limit the number of trays used in growout ponds. However, it is important to have a sufficient number to avoid intensifying interanimal contact. Penaeid shrimp are not territorial, but they tend to avoid prolonged contact with each other by taking evasive action. This may suppress the effect of feeding attractants released from feeds and increase competition among animals.

Under semi-intensive stocking densities (up to 25 shrimp per square meter), 25 to 30 trays per hectare are typically used. Therefore, each tray serves up to 10,000 shrimp in an area of 300 to 400 square meters. If higher densities are used, one tray per hectare is added for every shrimp stocked per square meter (for example, 40 shrimp per square meter = 40 trays per hectare).

Setting up the trays

Anchor poles are installed in the pond bottom while it is still dry, and homogeneously distributed to assure shrimp access to the feed. This promotes more food encounters, re ducing the time shrimp spend locating feed. Poles are not planted in areas that shrimp normally avoid, such as very shallow areas and corners. They are normally placed in straight lines 20 meters apart and 5 to 10 meters from pond sides.

The trays are tied to and left suspended on the anchor poles prior to filling the pond with water. After harvest, the poles are relocated to allow recovery of the pond bottom in areas where trays had been previously installed. In large ponds, anchor poles are completely removed between cycles to allow tractors to till the soil, and brought back only after the ponds are dried and limed.

Nursery tanks

Instead of nursery ponds, Brazilian shrimp farmers use intensive, round nursery tanks with water volumes of 30,000 to 80,000 liters. Trays are first used in nurseries with PL<sup>10-15</sup>, with 5 to 10 percent of the daily ration distributed in three to five trays, and the remainder broadcast over the culture area.

Feed distribution

During the first two weeks of pond culture, artificial food is manually dispersed over the pond, especially in the periphery, where juveniles or pre-adults tend to concentrate. During this time, farmers gradually start to distribute a portion of the ration in trays. Feed is distributed only in trays after the second week. Fiberglass kayaks equipped with a large container in the front or back are used to take the feed to the trays.

Uneaten feed collected from the trays is stored in the container while fresh feed is distributed. This is done with volumetric plastic containers that are graduated to dispense 50, 100, 150, 200 and 250 grams of feed. At three feedings per day, one worker may cover up to seven ha of culture area.

Feeding times

Penaeid shrimp appear to feed continuously and empty their guts within four hours after a full meal is ingested. Most feed appears to be consumed 30 min after its distribution. In Brazil, farmers feed the shrimp only during daytime, since in the dark it is difficult to determine the amount of feed left in trays. The time interval given between feeding ranges from three to six hours. Shrimp may typically be fed at 6 a.m., 11 a.m. and 3 p.m., but feeding times change from one farm to another.

Frequency

Feeding frequency varies according to the level of stocking density and the shrimps’ growth stage. Because labor requirements increase with higher feeding frequency, only two or three daily feedings are usually feasible. In ponds greater than 7 ha, feeding never exceeds three times per day. However, four feedings have been used in the late stages of culture at densities of up to 45 shrimp per square meter.

Feed collection

Feed left in trays from previous feedings is collected for weighing or left in trays to allow complete consumption. However, most farms collect all unconsumed feed at each feeding period, particularly that remaining from the previous day. To reduce feed costs and the time required for distribution, some farms still prefer to collect only overnight leftovers. During collection it is important to rinse and brush the tray clean with pond water.

Adjusting feed rations

Feed demands increase gradually with shrimp biomass, particularly after molting periods and during the intermediate stages of culture. In Brazil, farm employees are trained to visually determine the amount of feed left in trays from the previous feeding period. This allows individual adjustments of feed rations to each feeding tray based on the consumption levels that occurred in that specific feeding area.

Competent workers needed

Farm workers are typically trained intensively and motivated by incentives based on the yield or food-conversion ratio (FCR) of the ponds they manage. To visually estimate the amount of unconsumed feed, workers first practice with trays immersed in 1,000-liter tanks before being appointed to work as feeders in ponds. A more experienced worker randomly inspects ponds and checks whether feed is being correctly administered and trays are well brushed.

Controlling feed amounts

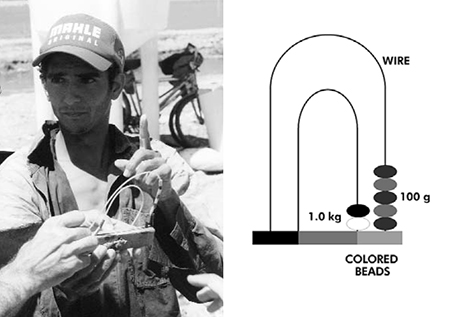

A meter is fixed on the top of each anchor pole to help control feed amounts placed in trays (Fig. 1). Meters are made of two U-shaped wires with small, colored beads to represent the amount of feed given at each feeding time. Beads placed on the outer wire represent grams of feed applied, while beads on the inside wire indicate feed quantities in kg. Each outer bead may represent 100 grams each, while the inner ones represent 1 kg each.

Both wires are attached to a small piece of wood, with the edges painted in two distinct colors showing the direction beads have to be moved. One meter is generally used per feeding tray, but the number may also vary according to the number of feedings per day. In the first early-morning feeding, a full meal is often given, regardless of the amount of uneaten food left from the previous day.

Using meters

The following example illustrates how the meters are used (Table 1). An employee is told to place 300 grams feed per tray in a grow-out pond. At 6 a.m., he applies the full-ration meal in all trays, although in some cases he might have noticed uneaten feed from yesterday’s feeding. The feeder ends the feeding by moving three beads to the opposite side of the meter to record the amount of feed administered (3 beads = 300 grams).

At the 11 a.m. feeding, there were 100 grams of feed left in one tray. This time, the worker subtracts the amount of feed allocated at 6 a.m. from the amount left in the tray (100 grams). He places 200 grams of feed, moves two beads to the left, and collects all uneaten feed for disposal. At 3 p.m., the same protocol is followed. Feed adjustments can also follow the guide presented in Table 2.

Conclusion

Shrimp farmers in Brazil have adapted the Peruvian feeding tray system very successfully to reduce feed waste and achieve FCR lower than those in several other regions. This practice also helps to reduce water quality problems in ponds and improve effluent water quality. The only disadvantage is that this method is very labor-intensive. However, increased pond productivity and decreased management costs for feed and water quality often offset the increased cost of labor.

(Editor’s Note: This article was originally published in the February 2001 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Alberto J.P. Nunes, Ph.D.

Agribrands do Brasil Ltda.

Paulínia, SP, Brazil[114,98,46,109,111,99,46,115,100,110,97,114,98,105,114,103,97,64,110,112,106,111,116,114,101,98,108,97]

-

Arul Victor Suresh, Ph.D.

Agribrands International Inc.

St. Louis, Missouri, USA[109,111,99,46,115,100,110,97,114,98,105,114,103,97,64,115,114,111,116,99,105,118]

Related Posts

Health & Welfare

A case for better shrimp nutrition

Shrimp farm performance can often be below realistic production standards. Use proven nutrition, feeds and feeding techniques to improve profitability.

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Health & Welfare

A look at aquaculture in Guyana

With its large quantities of water and little industry to pollute it, Guyana has the potential to become a greater player in global aquaculture.

Responsibility

A look at integrated multi-trophic aquaculture

In integrated multi-trophic aquaculture, farmers combine the cultivation of fed species such as finfish or shrimp with extractive seaweeds, aquatic plants and shellfish and other invertebrates that recapture organic and inorganic particulate nutrients for their growth.