China produces 95 percent of the freshwater pearls sold in the world market

Freshwater pearl culture technology was developed in China some 2,000 years ago. However, commercial freshwater pearl culture dates back only to the late 1960s and early 1970s, when output was about 500 kg annually. Production then increased geometrically to about 20 metric ton (MT) in 1972, and hundreds of tons since 1980. Annual production exceeded 2,000 MT in 1995 and 1996.

Several species of freshwater mussels produce pearls in China. Both the triangle sail mussel (Hyriopsis cumingii) and wrinkle comb mussel (Cristaria plicata) are widely used for pearl production, but the former species yields higher-quality pearls.

Industry development

In 1968, freshwater pearl culture began in the provinces of Jiangsu and Zhejiang using mussels collected from rivers, lakes, and ponds. Because of the successful propagation of pearl mussels, the activity expanded rapidly to contiguous areas. At present, freshwater pearls are produced mostly in Jiangsu, Zhejiang, Anhui, Jiangxi, Fujiang, Hunan, and Hubei.

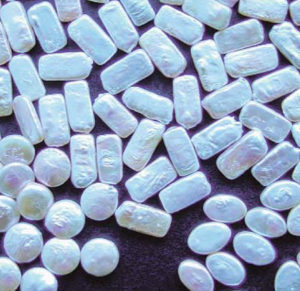

During the 1980s, the ricelike cultured pearls from wrinkle comb mussels dominated Chinese production. Gradual changes in technology, and more importantly the mussel species used, resulted in the production of greater quantities of larger and more lustrous, round, near-round, and baroque cultured pearls with a variety of colors from triangle sail mussels since 1984.

Today, there is great demand for cultured freshwater pearls. China produces 95 percent of the freshwater pearls sold in the world market. Exports have increased rapidly since the first trade of 1 kg took place in 1970, reaching about 600 MT annually.

Production technology

In an operation procedure, slices of tissue from the edge of a mussel’s mantle, near the pallial line, are transplanted. The slices are made there because the nacre secretion capacity of this part of the mantle is the greatest.

The mantle slices are transplanted into the mantle tissue at the posterior part of a living mussel. The slices undergo cell division and multiplication to form pearl sacs. The pearl sacs then secrete nacre and create pearls.

The number of transplanted mantle slices used depends on mussel size. About 25 to 30 slices can be transplanted into a mussel of 6-cm length, with 12 to 15 slices in each side. Therefore, 25 to 30 pearls can be produced from a single mussel.

The best season for this operation depends on water temperature. When the water temperature is 15 to 25 degrees-C, mussels have active metabolisms with high survival rates of mantle cells, recover rapidly from the operation wound, and quickly form pearl sacs and secrete nacre. These are important factors in producing good-quality pearls. In China, March to May and September to October are the best times for the operation and transplant.

Nuclei and image pearls

Along with the mantle tissue slices, nuclei are inserted into the cavity between the shell and mantle of the operated mussels. The pearl sacs surrounding the nuclei secrete nacre over the nuclei and produce nuclei pearls.

Pieces of shell make the best nuclei material. They can be manufactured in different shapes to produce shaped nuclei pearls. Image pearls get their shape from that of the sculpted nuclei used to create them. The original sculpture can be made from wax, shell, plastic, steel, or other materials with a distinct convex surface design.

Care of implanted mussels

Implanted mussels can be held in net bags, net cages, or net folders hung from plastic ropes. Foam, glass balls, bamboo sections, and plastic bottles are used as floats to support the containers. The plastic ropes are tied with stakes made from wood or bamboo.

Mussels should be reared in ponds, rivers, reservoirs, or lakes that are free from pollution and disease vectors. Pearls will be produced within several years of culture. Careful management is very important during this period, as it affects the quality and quantity of pearls produced, particularly in terms of water quality and management of natural food production through fertilization or manuring.

(Editor’s Note: This article was originally published in the June 2003 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Hua Dan

Freshwater Fisheries Research Center

Chinese Academy of Fisheries Sciences

Wuxi City 214081

Jiangsu Province, China -

Gu Ruobo

Freshwater Fisheries Research Center

Chinese Academy of Fisheries Sciences

Wuxi City 214081

Jiangsu Province, China -

Wen Haibo

Freshwater Fisheries Research Center

Chinese Academy of Fisheries Sciences

Wuxi City 214081

Jiangsu Province, China

Tagged With

Related Posts

Responsibility

Carp polyculture in India

Carp polyculture with other species originally established through government projects has grown in India thanks to the application of advancing technologies and private financial investments.

Intelligence

From queen to common, once-rare pearls now suffer from overproduction

Pearls were once regarded as precious gems until researchers working with all the major species of pearl-bearing mollusks figured out how to produce the animals by the millions.

Responsibility

Integrated marine aquaculture-agriculture: Sea farming out of the sea

Aquaponic systems are robust, management is not difficult, and the synergies between fish and plants make vegetable production more profitable than aquaculture alone. The lion’s share of marine agriculture involves salt-tolerant halophytic plants used as food or feed, or in energy production.

Aquafeeds

Local aquafeed development in Namibia

As more-intensive methods for tilapia and catfish culture become popular in Namibia, practical diets need to be formulated using local ingredients such as maize, millet, wheat bran and fishmeal to reduce feed costs.