Primary problems involve Salmonella and Listeria monocytogenes

Cooked shrimp remains one of the most popular seafood products in the world. Whether from tropical or cold water harvests, or aquaculture ponds, the demand for an assortment of cooked shrimp remains strong in all established and emerging markets. The difference in commercial success depends on processing knowledge and experience to assure product safety while protecting quality and maintaining yield.

Regulatory, market concerns

Although cooked shrimp remains one of the safest ready-to-eat foods, regulatory and market concerns continue to question cooking procedures and potential postcook contamination with pathogenic bacteria that have caused foodborne illnesses.

The primary bacterial problems involve Salmonella and Listeria monocytogenes. Previous regulations in the United States and European Union simply stated zero tolerance for any Salmonella species on any cooked or raw shrimp and zero tolerance for the specific species L. monocytogenes on cooked shrimp.

The U.S. Food and Drug Administration’s guidelines for seafood cooking in retail or restaurant operations call for an internal product temperature of at least 63 degrees-C for 15 seconds based on kill rates for Salmonella. More recent regulations focus on the more heat-resistant Listeria.

Current FDA regulations assume Listeria can be found in the internal parts of shrimp and recommend cooking methods that provide a 6-D reduction in L. monocytogenes (Table 1). One D-value is simply the time at a specified internal temperature required to kill 90 degrees of the targeted bacteria. Theoretically, a 6-D kill means 1,000,000 initial bacteria can be reduced to approximately zero. The 6-D process also has a significant safety margin.

Otwell, Seafood cooking guidelines, Table 1

| Internal Product Temperature | Time for 6-D Process (minutes) |

|---|

Internal Product Temperature | Time for 6-D Process (minutes) |

|---|---|

| 63° C | 17.0 |

| 68° C | 3.7 |

| 74° C | 0.6 |

| 79° C | 0.1 |

Studies have shown that most seafood has far less than 1,000 colony-forming units of L. monocytogenes/25 grams of product. In this case, a 3-D process would be sufficient to reduce the bacteria. One could argue that a 6-D process is overkill, but margins of safety must be considered in case of gross contamination or errors in processing.

Cooking system design

It is not difficult to design cooking systems that kill bacteria on shrimp, but the trick is to provide a safe kill without reducing product quality and value due to overcooking. A common solution has been to cook shrimp to an internal temperature of at least 74 degrees C. This temperature is considered to provide an instantaneous kill or near instantaneous 6-D process.

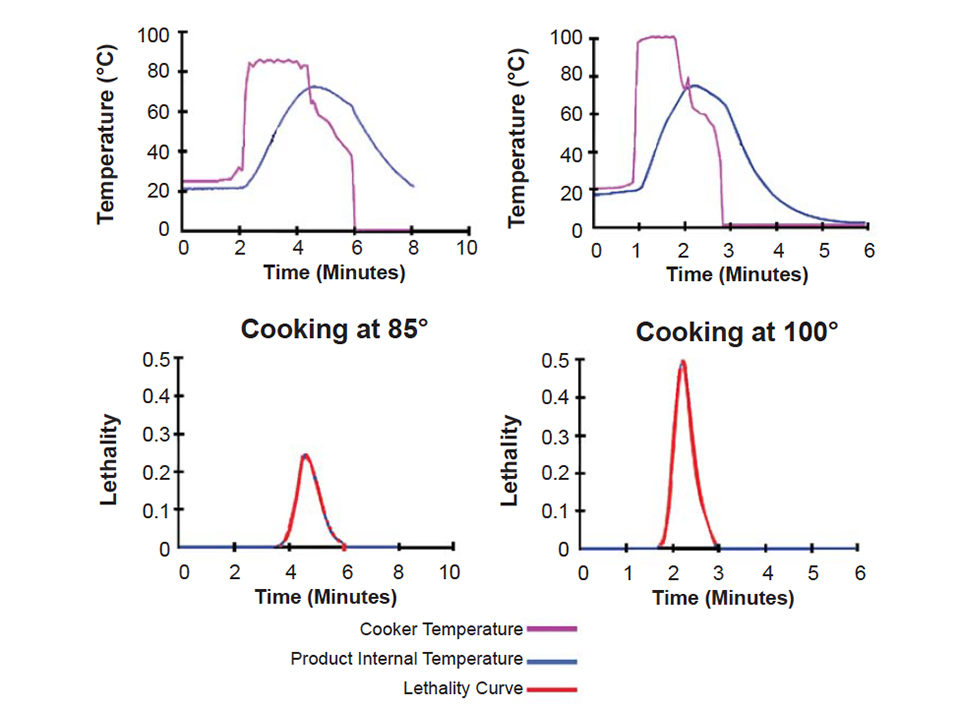

The approach is simple, but it can be difficult to control instantaneous processes that can continue heating the shrimp beyond the specified internal temperature. This can be an adequate approach in some situations for certain shrimp, but more experienced firms realize better product quality and higher yields with cooking methods and equipment that provide an acceptable kill without internal temperatures at or above 74 degrees-C (Fig. 1). The more controlled approaches involve validations for thermal processes that combine the cumulative effects of cooking temperature and time.

Validation, verification

The advanced cooking methods are validated for various shrimp species and sizes to account for different cooking characteristics. Periodically, these procedures are verified during daily processing to provide routine measures for performance. The reward for this extra effort is a process that is in compliance with HACCP requirements for food safety while providing better yields and more-appealing shrimp texture and appearance.

The validation and verification procedures are not difficult, but require some special equipment to monitor and record the progressive increases in product temperature throughout the cooking process. The resulting data can be quickly converted with existing computer programs to determine the bacterial kill provided by the process.

Differences in yield can range 5 to 15 percent higher than those achieved with the more aggressive instantaneous-kill processes. In some situations, the resulting product is preferred over less-controlled cooks.

(Editor’s Note: This article was originally published in the October 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Steve Otwell, Ph.D.

Aquatic Food Products Program

University of Florida

Gainesville, Florida 32611 USA -

Victor Garrido, M.Sc.

Aquatic Food Products Program

University of Florida

Gainesville, Florida 32611 USA -

Murat Balaban, Ph.D.

Aquatic Food Products Program

University of Florida

Gainesville, Florida 32611 USA

Tagged With

Related Posts

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Health & Welfare

Aiding gut health with a natural growth promotor

A study with Nile tilapia conducted in commercial production cages in Brazil showed the potential – in the absence of major disease threats – of a commercial, natural growth promotor that modulates the microbiota (inhibiting growth of pathogenic bacteria and promoting growth of beneficial bacteria) and inhibits quorum sensing.

Aquafeeds

Biosecurity protocols needed for shrimp feeds, feeding practices

Shrimp aquafeeds – live, fresh or formulated – should not be an entry point of potential pathogens to the shrimp and/or to their culture systems.

Intelligence

Critical decisions for shrimp harvesting and packing, Part 2

The decision to harvest involves consideration of various factors, including market prices, customers’ need, biomass and condition of the animals and others. Several steps are involved, most aimed at maintaining maximum quality of the animals as they are harvested, sacrificed, treated and transported to the plant and processed and packed.