Intensive systems provide continuous culture with daily harvests, reducing labor and space

One of the limiting factors in the operation of marine finfish hatcheries is the production of the marine rotifers Brachionus rotundiformis and Brachionus plicatilis as food sources for first-feeding larvae. Many hatcheries rely on the traditional batch culture method for rotifer production. This technique requires several culture tanks inoculated and harvested at timed intervals to ensure daily harvests of adequate rotifers. Batch culture is labor-intensive, requires a large portion of hatcheries’ floor space, and often is unpredictable.

Intensive rotifer systems are currently being developed worldwide to provide continuous culture with daily harvests from one tank. They can significantly reduce labor and space requirements while providing a reliable supply of rotifers.

Intensive production

Successful intensive culture of rotifers requires an adequate supply of food for the cultures. The development of condensed microalgae has allowed culturists to provide rotifers with sufficient feed without the need to maintain production of live microalgae in the hatchery.

One of the more popular species of microalgae used in the United States is the marine microalgae Nannochloropsis oculata. This algae is readily available as a preserved paste that can be frozen and stored for several months.

Pilot system

A study conducted at the University of North Carolina Wilmington, in North Carolina, USA, tested the performance of a pilot-scale high-density, continuous recirculating system for the rotifer B. rotundiformis fed condensed Nannochloropsis oculata.

The system consisted of a square 190-l culture tank filled with 120 liters of 16- to 24-ppt brackish water. Water from the culture tank was drained through a center stand pipe with a mesh screen into a sump tank, then pumped back to the culture tank at a rate of 500 percent per day.

Solids removal, aeration

A portion of the water was diverted to a foam fractionator to remove dissolved solids and fine particulate matter. Pure oxygen was delivered through a 15-cm diffuser to maintain dissolved oxygen levels of 4.00 to 16.7 milligrams per liter. To provide adequate tank circulation, diffused aeration was provided by four air diffusers placed around the perimeter of the tank.

Water temperature was maintained at 28.0 degrees-C by a submersible heater. To remove suspended solids, four viline filter mats suspended in the culture tank were removed and rinsed daily. In addition, a small air-lift filter in the center of the tank circulated water over a vilene canister filter.

Neutralizing ammonia

To neutralize toxic free ammonia in the culture water, a commercial water conditioner was added daily at a rate of 0.25 grams per million rotifers. Dissolved conditioner was dripped into the water from a container suspended over the tank over a 24-hour period.

The neutralizing of the free ammonia released hydrogen ions, so it was necessary to buffer the system by adding 5 grams of sodium bicarbonate per day to the water conditioner solution to maintain an average total ammonia nitrogen level of 35.4 milligrams per liter.

Feeding

A feeding rate of 1.5 grams of algae paste per 106 rotifers per day was initiated once the culture reached a density of 3,000 rotifers per milliliter. During the start-up period, slightly higher feed rates were used to ensure adequate feeding of the rotifer culture. The diluted algal paste was added to the culture tank over a 24-hour period by a peristaltic pump.

Operation, production

The system was initially stocked at a density of 600 to 900 rotifers per milliliter and monitored daily. Once the density reached 3,000 rotifers per millileter, the culture tank was harvested daily by draining the appropriate volume of water. If the culture density fell below that level, rotifers were still harvested to stimulate reproduction and maintain a stable culture.

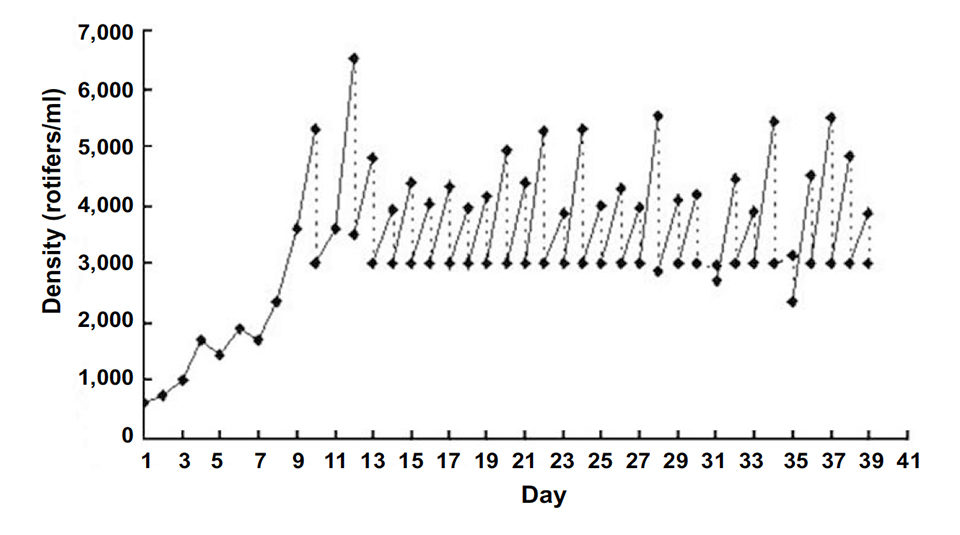

The culture was maintained for 39 days, a sufficient period to demonstrate long-term stability. As a precautionary measure, every 14 to 23 days, the entire system was drained, cleaned, filled with new water and restocked at 3,000 rotifers per milliliter. The trial yielded an average daily harvest of 178 million rotifers (Fig. 1).

(Editor’s Note: This article was originally published in the August 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Christopher D. Bentley

University of North Carolina Wilmington Center for Marine Science

7205 Wrightsville Avenue

Wilmington, North Carolina 28403 USA -

Patrick M. Carroll

University of North Carolina Wilmington Center for Marine Science

7205 Wrightsville Avenue

Wilmington, North Carolina 28403 USA -

Amy M. Riedel

University of North Carolina Wilmington Center for Marine Science

7205 Wrightsville Avenue

Wilmington, North Carolina 28403 USA -

Wade O. Watanabe, Ph.D.

University of North Carolina Wilmington Center for Marine Science

7205 Wrightsville Avenue

Wilmington, North Carolina 28403 USA

Related Posts

Health & Welfare

Algae alternatives serve in larval rearing of sea bream

Sea bream fry are produced using the greenwater technique in which microalgae are added to larval-rearing tanks during the first 20 to 30 days after hatching.

Health & Welfare

Green water culture of California halibut larvae

Although aquaculture offers potential for the production of California halibut, several aspects of production have yet to be optimized.

Health & Welfare

Microbial flocs for aquaculture

Microbial flocs consist of a variety of bacteria, fungi, microalgae and other organisms suspended with detritus in culture water.

Aquafeeds

Novel reactor developed for indoor, high-density production of diatoms

The development of this reactor for the indoor cultivation of non-suspended microalgae like important diatoms such as Amphora spp., and the cellular dry matter values produced in this study will help bio-filming science support the development and improvement of in situ feed supplementation for fish and shrimp ponds, particularly in desert environments.