Study demonstrates viability of lined ponds and high stocking densities

Culture of Pacific white shrimp (Litopenaeus vannamei) in ponds with plastic liners began in 2013 in the Special Region of Yogyakarta, and then developed along the southern coastal area of Central Java. Soils in this area include sand dunes, acid to neutral pH, low conductivity and a water permeability of 5 cm/hour. Water is pumped from groundwater wells and has salinities of 10 to 25 ppt.

Currently, there are an estimated 1,100 ponds ranging in size 1,000 to 4,500 square meters. Initially, farms successfully produced shrimp crops but then the onset of White Feces Syndrome seriously affected production. Farmers have erroneously assumed that to increase production and profits, a higher stocking density is needed, even with limited technology, resources and water quality.

Widely reported data on L. vannamei culture systems and stocking densities are very diverse, and to date, its optimum density for production in sandy soils is not available. This article (adapted and summarized from the original publication in Revista Acuacultura – Cámara Nacional de Acuacultura, No. 126, December 2018) reports on a study carried out to determine the effect of stocking densities of Pacific white shrimp and its productive performance in an intensive system using ponds built on sandy soils.

Study setup

This study was conducted on the coast of the village of Keburuhan, Ngombol Purworejo district, Central Java. This location includes sandy and clay farm land and aquaculture areas. Nine plastic-lined ponds (3-by-4-by-1 meters) were built on sandy soil, and filled with water (80 cm water column) from a 20-meter well. Each pond had a 1 HP paddlewheel for aeration and was stocked with L. vannamei PL-9 seedstock from a commercial hatchery.

The shrimp were fed with commercial feeds (30 percent), including meal, crumbs and pellets, applied depending on animal size, and amounts were adjusted after day 25 after stocking according to the shrimp density of each treatment.

Water quality monitoring and shrimp condition assessments were carried out regularly. Periodic pond water exchanges were carried out to maintain pond water quality, from 1 to 5 percent until the second month of culture, and then 5 to 7 percent until harvest. To reduce the organic matter, the bottom of the ponds were siphoned after 25 days of shrimp culture and then, every week. Shrimp were harvested after reaching a market size of approximately 12 to 13 grams, or after 75 days of culture.

For detailed descriptions of the experimental design, ponds and equipment; animal husbandry procedures and water quality monitoring; data collection and statistical analyses; and references, please contact the first author.

Results and discussion

The results of our study demonstrate the viability of L. vannamei culture in sandy soil, lined ponds using relatively high shrimp densities. The data for final weight, survival rate, daily growth, feed conversion ratio (FCR) and biomass are shown in Table 1. Average final weights varied between 9.58 ± 0.54 and 12.93 ± 0.7 grams, and the treatment with the density of 300 shrimp per square meter was significantly different to the treatments with 100 and 200 shrimp per square meter.

Resulting daily growth rates ranged between 0.1118 ± 0.006 and 0.1526 ± 0.011 grams per day, with significant differences between the density treatments, and with an inverse relationship between high density and weight. Survival rates were significantly different among all treatments; the 100 animals per square meter treatment had a survival of 96.54 percent, followed by the 200 and 300 shrimp per square meter treatments, (83.46 and 64.98 percent, respectively.

Samadan, sandy ponds, Table 1

| Parameter | 100 (shrimp per square meter) | 200 (shrimp per square meter) | 300 (shrimp per square meter) |

|---|---|---|---|

| Final weight (g) | 12.93±0.7a | 10.18±0.66b | 9.58±0.54c |

| Survival rate (%) | 96.54±1.47a | 83.46±5.72b | 64.98±4.58c |

| Absolute growth (g/day) | 0.1526±0.011a | 0.1225±0.08b | 0.1118±0.006c |

| FCR | 0.99±0.07a | 1.47±0.005b | 2.00±0.05c |

| Biomass production (kg/ha) | 14.99±1.09a | 20.33±0.14b | 22.37±0.57c |

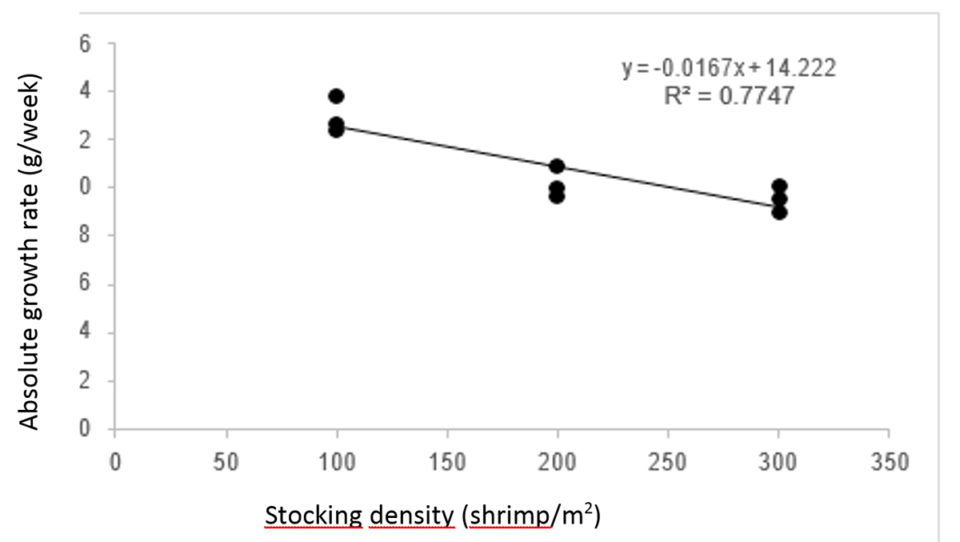

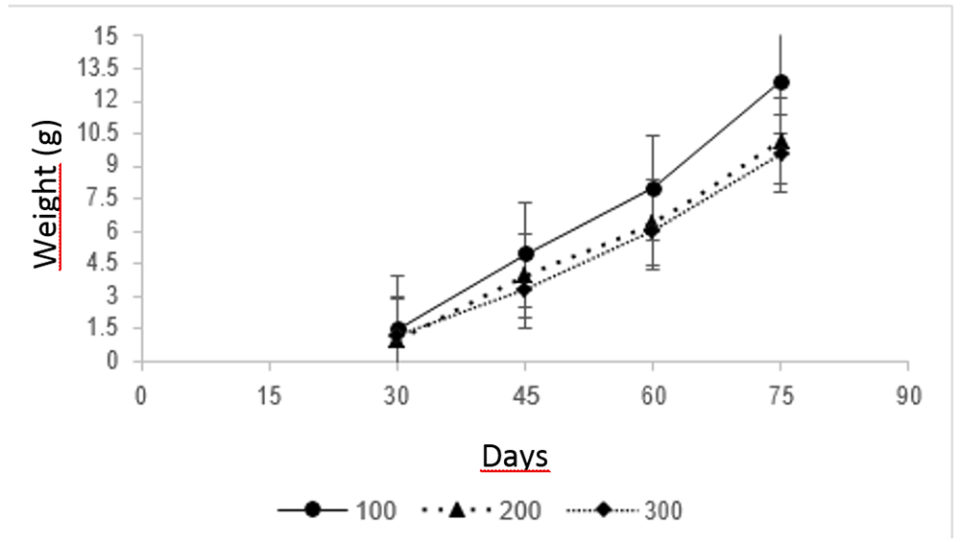

The shrimp biomass produced ranged from 14.99 ± 1.09 to 22.37 ± 0.57 kg per square meter, with significant differences between density treatments. The feed conversion rate (FCR) varied between 0.99 ± 0.07 and 2.00 ± 0.05, and varied significantly between density treatments. Figs. 1 and 2 show growth rates and mean weights after the 75 days of culture in the study.

Regarding water quality parameters, water temperature in the study ponds ranged from 29.23 to 29.60 degrees-C, pH 7.96 to 7.99, salinity 22.07 to 25.07 ppt, dissolved oxygen 4.24 to 4.51 mg/L, nitrite 1.35 to 1.96 mg/L, ammonia 1.63 to 2.49 mg/L, total organic matter (TOM) 185.15 to 248.20 mg/L and turbidity 38.07 to 39.64 cm.

Perspectives

The culture of L. vannamei in sandy ponds with liners is effective when stocking at a density of 100 shrimp per square meter. This stocking density produced better growth rates (0.1526 grams per day), survival rates (96.5 percent) and FCR (0.99). The stocking density of 300 shrimp per square meter produced the highest biomass, 22.37 kg per cubic meter,but with low final weights and survival rates compared to the lower stocking density schemes. Effectively culturing L. vannamei in sandy, lined ponds requires attention to the seasons as well as to water management.

References available from first author.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Gamal M. Samadan

Faculty of Fisheries and Marine Science

Khairun University Ternate, Indonesia[109,111,99,46,108,105,97,109,103,64,52,55,110,97,100,97,109,97,115,46,109,103]

-

Rustadi

Department of Fisheries and Marine Science

Gadjah Mada University

Yogyakarta, Indonesia -

Djumanto

Department of Fisheries and Marine Science

Gadjah Mada University

Yogyakarta, Indonesia -

Murwantoko

Department of Fisheries and Marine Science

Gadjah Mada University

Yogyakarta, Indonesia

Related Posts

Responsibility

Appraising pond liners for shrimp culture

The use of plastic-lined ponds by shrimp farmers can significantly improve production efficiency, support more production cycles per year, and higher mechanical aeration rates and stocking densities. The capital cost of lining ponds can be very significant, so a thorough feasibility analysis is recommended when considering this production tool.

Responsibility

Aquaculture certification steers to zone management

Zone management is an emerging field of interest among industry stakeholders. Experts say it will aid in controlling diseases and in determining carrying capacities. We take a closer look at the management tool’s potential.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Responsibility

Bacterial amendments in shrimp grow-out ponds

Pond microbial communities are a critical and often overlooked component of aquaculture ecosystems. Bacterial amendments like probiotics provide significant support to shrimp farmers around the world.