Farmers’ new choice for better growth, feed conversion

As feed continues to represent the highest-cost input in aquaculture worldwide, the use of automatic feeders is proving to be an important approach to lowering production costs, improving animal growth and feed-conversion rates, and reducing labor requirements.

Although automatic feeders have been used in fish farming, automatic feeding systems for shrimp farming were only recently developed in Thailand. According to the Thailand Department of Fisheries, feeding machines are successfully used by more than 60 percent of the shrimp farmers in the country.

Automatic feeders are quite suitable for large ponds because they are designed to distribute feed in a radius of about 10 m. The efficiency of a feeding machine relates to the size and shape of the pond it serves. If a feeder is used in a small square pond of less than 1 ha area, it can reach up to 600,000 shrimp, while in large rectangular ponds over 2 hectares, the efficiency may go down to 300,000 shrimp/machine.

Feeder placement

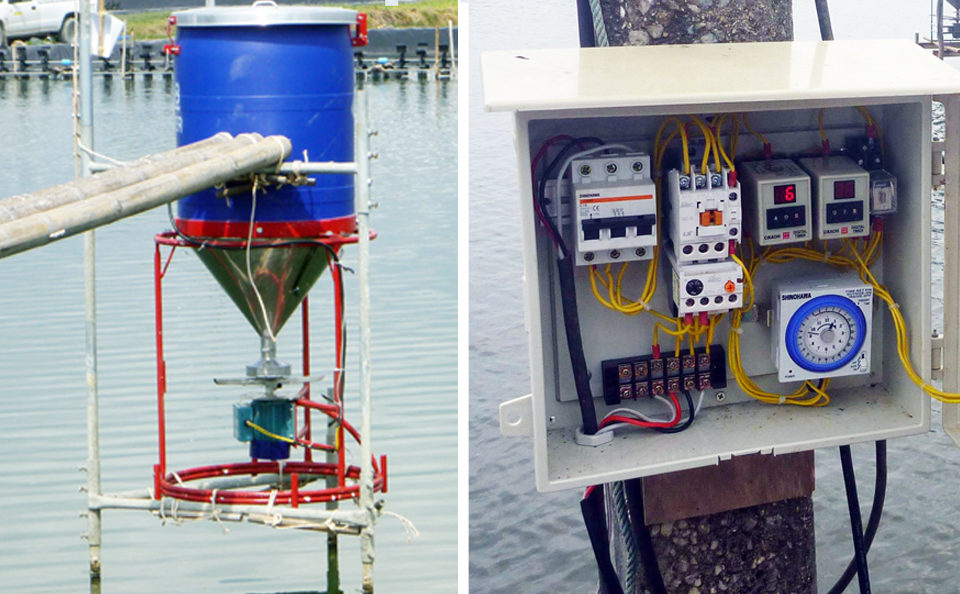

The feeding machine should be placed on a small pier that extends 12 to 15 meters into the middle of the pond and positioned in the deepest area. The feed broadcasted by the machine should not be too close to aerators, because the current caused by the aerators could push the feed to where the shrimp cannot easily reach it.

The spout of the feed dispenser should be about 60 to 80 cm above the surface of the water. The higher the machine is placed, the larger the feed broadcast radius will be. If two feeding machines are needed for one pond, they should be placed parallel to each other and 25 to 30 meters apart, so the feed distribution does not overlap. If the pond is long and narrow, the machines should be placed at opposite ends.

Automatic feeding

Automatic feeding machines should first be used when shrimp are 15 to 25 days old or when farmers start using pellets of 1.8- to 2.0-mm diameter. Before that, feeding should be done with traditional methods. Some Thai farmers begin to use the automatic feeders when the first estimates of survival rate and shrimp size are done.

A set of timers control the feed-broadcasting time in ranges of a few seconds to several minutes, depending on the desired feed dose, shrimp size and biomass. Most farmers start with shorter broadcasting times and intervals when the animals are small, but as shrimp grow larger, periods and intervals get longer (Table 1). Another type of timer controls the periods of time the automatic feeders work during the day. Some farmers prefer periods from 7 a.m. to 8 p.m., and others use the automatic feeders 24 hours a day.

Limsuwan, Common feed broadcast periods, Table 1

| Shrimp Size (g) | Broadcast Time (seconds) | Interval Between Broadcasts (minutes) |

|---|

Shrimp Size (g) | Broadcast Time (seconds) | Interval Between Broadcasts (minutes) |

|---|---|---|

| 1-5 | 5 | 2 |

| 6-12 | 18 | 5 |

| More than 12 | 30 | 10 |

Evaluating consumption

Feed trays are used to evaluate consumption, but only two trays are needed for each feeding machine. The first tray should be located 1.5 to 2.0 meters from the machine, and the second tray placed 6.0 to 8.0 meters away. They should not be allowed to touch the pond bottom, but should be suspended 10 to 15 cm above the bottom.

Trays should be used where plenty of feed is dispersed, or at least as much as in other areas. No feed should be applied manually on the trays. Farmers usually check trays every two hours, four or five times daily. If there is leftover feed on the trays, the feeding machine should be adjusted for longer intervals between feed dispersals, or the broadcast rate can be reduced. Ideally, no feed should be left in the trays. Farmers should check average shrimp weights every week and adjust feeding rates as necessary.

Less waste, better water quality

Automatic feeders are especially suited to feeding Pacific white shrimp, which like to eat their food while swimming swiftly in the water. If small amounts of feed are dispensed over a wide area of the water surface at regular short intervals, there is little chance of finding leftover feed on the bottom of the pond. Overfeeding is thus rare during automatic feeding, and pond bottom quality is maintained to the end of the grow-out cycle.

In contrast, during hand feeding, large amounts of feed pellets are applied at once. Some of the feed can remain uneaten for long periods, losing attractants and gradually leaching significant amounts of nutrients to the water. If this feed is not eaten, the concentration of organic matter in the pond will increase, as well as the ammonia concentration at the pond bottom. As a result, dissolved-oxygen values drop and negatively affect shrimp growth, survival and feed conversion.

Feeding recommendations

- If more than one feeder is used in a pond, the feeding machines should be turned on at the same time, so feed is distributed all over the pond at the same time.

- Automatic feeding should typically be done during the day, which makes shrimp consume natural productivity at night. If machines are used 24 hours without supervision at night, oxygen concentrations can drop below normal levels.

- Farmers should consider that larger-sized feed pellets are broadcasted farther from the feeding machine and reach a slightly larger radius than smaller-sized pellets reach.

- When a wide range of sizes in the shrimp population occurs, small shrimp can be fed manually until the proper amount of feed has been determined. Then automatic feeders should be used again.

- In areas of strong winds, it is advisable to place nets on the shores of ponds near automatic feeders so feed pellets do not drop on land.

- If a large amount of feed is left in feed trays, and the weather is overcast or rainy, feeders should be turned off for a few hours during the day.

(Editor’s Note: This article was originally published in the March/April 2013 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Dr. Chalor Limsuwan

Professor

Department of Fishery Biology

Kasetsart University

50 Phaholyothin Road Chatuchak

Bangkok, 10900 Thailand -

Dr. Carlos A. Ching

Technical Assistance Manager

Nicovita – Alicorp SAA

Callao, Peru

Tagged With

Related Posts

Innovation & Investment

Acoustic control improves feeding productivity at shrimp farms

In systems recently developed for shrimp farms, passive acoustic-based technology enables sensor-based control of multiple automatic feeders. Improved growth and feed conversion have been recorded at commercial farms using the technology.

Intelligence

A land grab for salmon (and shrimp) in upstate New York

The operators of Hudson Valley Fish Farm see their inland locale as a pilot to prove that land-based fish farming, located in close proximity to major metropolitan markets, can be successful.

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.