Oritain: A farm’s unique forensic characteristics give its products a counterfeit-proof traceability profile

The price of seafood is strongly influenced by its provenance. And any brand tied to origin knows that putting a place on a label conveys quality, safety and trust.

The price of seafood is strongly influenced by its provenance. And any brand tied to origin knows that putting a place on a label conveys quality, safety and trust.

Traceability, therefore, is top priority for globally traded food supplies, and seafood certainly fits that bill. But is a QR code, a barcode or a certification logo enough proof to say that the shrimp in the pack is actually from Ecuador? Or that the salmon is from surely from Scotland?

Some valuable brands are finding that to provide assurance of authenticity and prevent economic fraud – which costs the global food business more than $50 billion a year, according to the Michigan State University Food Fraud Initiative – they must go beyond written or even digital records.

An emerging service for food products, aimed at protecting companies’ reputations, offers a scientific solution to fraud. New Zealand company Oritain says farmed food products such as milk, fruit, honey, meat, wine, cheese and even fish, can earn their own unique identification marker that’s virtually impossible to counterfeit – something akin to a fingerprint.

A chemical fingerprint, to be precise.

How it works, in a nutshell: Fish raised on a farm eat the same food. The river, lake or ocean water they all share boasts a suite of natural characteristics, some from nearby soils. A comprehensive measurement and analysis of stable isotopes and trace elements, along with genuine samples of the product and a proprietary statistical analysis, all go into creating a distinguishable profile that is stored in a database for future comparative testing.

You think of traceability as paper or electronic records, transferring from one segment of the supply chain to another. You try to reconstruct the story of that product along the supply chain. This is normally an exercise that takes some time, and it can be tampered with – it’s only as good as the information you put in.

There’s already a buzz about this technology. Oritain’s cutting-edge risk-mitigation service was first adopted by several Manuka honey brands. Manuka honey is a monofloral honey unique to New Zealand. Believed to have medicinal qualities, it fetches a price premium and is therefore ripe for rip-offs. Some produce and dairy companies are also on board with chemical fingerprints to protect their brands.

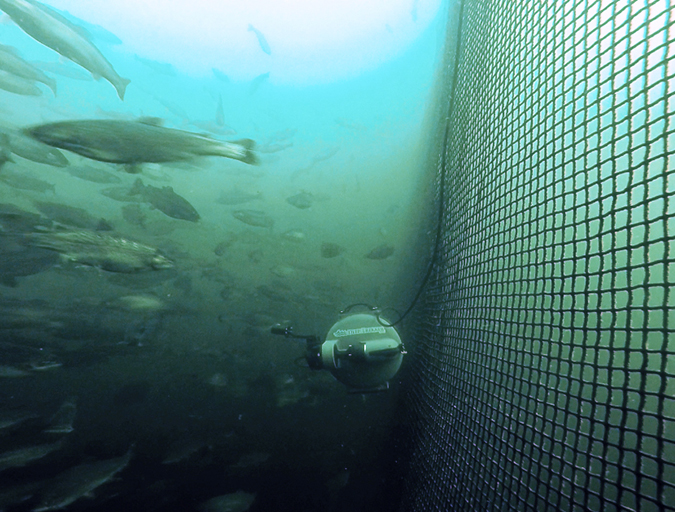

But aquaculture, practiced all around the world, could be the truly big frontier for this technology, and Oritain is now exploring its prospects with fish farms.

“It is a technology that is available for maybe 20 years but until recently not commercially offered,” Miguel Flavian, technical sales manager based at Oritain’s office in London, told the Advocate. “Our aim is to be the most trusted company in origin verification. Some want to know they have all the measures in place.”

New Zealand seafood company Sanford is working with Oritain to protect its Big Glory Bay seafood brand, which includes salmon, mussels and oysters.

“These species of seafood are unique to New Zealand, which is why we see the value in protecting the hard work that goes into creating the Big Glory Bay brand by working with Oritain. We are making sure the unique provenance of our Big Glory Bay range can be proven, not only proactively reducing the risk of fraud, but utilizing the strong opportunities from a storytelling point of view that this service presents,” the company said in a prepared statement. “Overall, we see Oritain as an integral piece to our Big Glory Bay brand.”

Relying heavily on chemistry and mathematics, the technology developed in close collaboration with the University of Otago in Dunedin, New Zealand. Several Oritain staff members either studied or worked at the school before joining the company, which was founded eight years ago.

Flavian refers to forensic traceability – which he stressed does not use DNA testing – as a “very disruptive” technology that makes even DNA testing appear limiting. While DNA can tell you that a piece of meat is from a cow or a pig, he said, forensic traceability can tell you where the cow or pig ate their lunch.

Oritain’s origin certification can prove if beef comes from grass-fed or grain-fed cows, whether any adulteration of food products has taken place, or if any dilution of the product has occurred.

“You think of traceability as paper or electronic records, transferring from one segment of the supply chain to another. You try to reconstruct the story of that product along the supply chain,” he said. “This is normally an exercise that takes some time, and it can be tampered with – it’s only as good as the information you put in.”

A food scandal – such as the horsemeat found in European beef supplies in 2013, or the melamine scare in Chinese exports nearly a decade ago – can erode the trust necessary to command high market prices. Oritain, which has partnered with Compass Group and Foodstuffs, is working with New Zealand mussel, trout and salmon companies and is exploring the vast opportunities that aquaculture provides.

With more and more food being traded internationally, brand protection is of growing importance for exports to what Flavian called “high-risk markets” like China. Oritain – which says its technology has a 92 percent “true positive” rate and a 96 percent “true negative” rate – has proven that fake labels were used there on fruit products being marketed as from New Zealand and calling for a higher price than domestic fruit.

“It’s a passport, if you want, that’s a unique way to identify products form one area,” he said. “Some companies are more open to it because they have had issues, or simply see the value to create a more robust supply chain.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Aquaculture Alliance

Portsmouth, NH, USA

Tagged With

Related Posts

Responsibility

Slow fish: Preventing waste via packaging

BluWrap shipping technology can cut the seafood industry's abysmal food-waste statistics by dramatically extending the shelf life of fresh product. Company CEO Mark Barnekow's mission is to get fresh fish off airplanes and onto ocean-bound cargo ships.

Responsibility

Ailing waterways hail the oyster’s return

The Lower Hudson Estuary and Chesapeake Bay, two waterways once home to thriving oyster beds, would welcome the shellfish’s return. Aquaculture initiatives in both areas aim to reinvigorate the water and the communities they support.

Innovation & Investment

Rise of the machines: Aquaculture’s robotic revolution

Technological advances are revolutionizing aquaculture. From airborne inspection tools to underwater drones, innovative robotics and automation technology are unveiling a brave new world of futuristic farming.

Innovation & Investment

Thinking outside the cage: Avant-garde aquaculture in Norway

Salmon farming in Norway is poised for an innovation boom. The biggest players are putting cutting technology in the water to solve some of the industry’s most persistent problems, such as sea lice, fish escape and waste management.